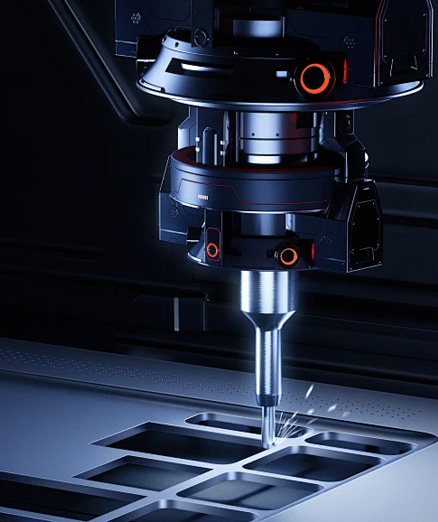

As the core energy source, CO₂ laser power supply plays a pivotal role in various non-metallic processing equipment. In laser engraving machines and marking machines, it achieves permanent marking from fine patterns to clear logos through precise control of laser power. In textile processing equipment such as garment cutting machines and portable cutting tables, stable laser output ensures that materials such as fabric and leather can be quickly and precisely cut, while automatically sealing the edges to effectively prevent the fabric from fraying.

In professional garment equipment such as laser bag-opening machines, the stability of the power supply ensures the consistency and precision of parts such as pocket openings. For laser cutting machines, the high-quality beam provided by the power supply ensures the precision and edge quality of the cutting die. When applied to high-power laser cutting machines, the robust power support enables them to process thicker non-metallic materials such as acrylic, greatly expanding the range of processing capabilities.

In summary, from fine marking to large-scale cutting, the performance of CO2 laser power supplies directly determines the processing quality, efficiency, and reliability of these devices, making them indispensable key components in modern intelligent manufacturing.

Its excellent stability and adjustability provide efficient and precise processing solutions for various industries.

Handheld portable laser marking machines and cleaning machines are gradually becoming important solutions for traditional processes in mechanical manufacturing due to their flexibility, efficiency, and environmental friendliness. They have significant advantages in portability, multi scenario applications, and wide material adaptability.

Handheld laser marking machines are widely used in mechanical manufacturing for permanent identification and traceability of components. They can quickly engrave serial numbers, QR codes, production dates, and other information on the surfaces of materials such as metal, plastic, and ceramics, ensuring full lifecycle management of products. Its portability allows for direct operation on large workpieces (such as machine tool bodies, engineering machinery structural components) or assembly sites, without the need to move the workpiece, significantly improving efficiency. Compared to traditional mechanical engraving or ink coding, laser marking has the characteristics of non-contact, consumable free, and strong anti-counterfeiting, especially suitable for tamper proof marking of high-precision components such as engine parts and bearings. At the same time, the marked content can be adjusted in real-time through software and linked with MES/ERP systems to meet the needs of flexible production, becoming an indispensable process in intelligent manufacturing.

Handheld laser cleaning machines are mainly used for efficient and environmentally friendly surface treatment in mechanical manufacturing. They can quickly remove oxide layers, oil stains, rust or coatings on metal surfaces, and are suitable for pre-treatment before welding/spraying, mold maintenance and part refurbishment. Its non-contact cleaning method avoids environmental pollution caused by chemical solvents or sandblasting, and can accurately adjust parameters to achieve layered cleaning, protecting the substrate from damage. This equipment is particularly suitable for cleaning complex structures of precision components such as hydraulic valve blocks and gears. It can remove oxides, rust, coatings, oil stains, molds, paints, and on-site maintenance of large machinery (such as ships and engineering machinery), significantly improving cleaning efficiency and in line with the development trend of green manufacturing.

Submit this form and we will contact you soon