Source:LZY Release Time:2026-01-12

As manufacturing progresses toward higher precision, greener practices, and greater intelligence, demands for workpiece cleanliness, environmental friendliness, and operational efficiency are becoming increasingly stringent. Traditional cleaning methods—such as chemical cleaning, sandblasting, and mechanical grinding—not only suffer from issues like environmental pollution, substrate damage, and high labor intensity but also struggle to adapt to modern production models characterized by flexibility, small batches, and diverse product varieties.

Against this backdrop, LZY the trolley-type pulsed laser cleaning machine (air-cooled) has emerged as an innovative green cleaning system solution for modern industry, distinguished by its high efficiency, non-destructive operation, zero pollution, and exceptional portability.

Core Advantages and Solution Highlights:

Portable and Mobile, Enabling Efficient On-Site Operations

The machine features an innovative integrated trolley design, with a total weight of approximately 25 kilograms and a compact footprint of less than half a square meter. This design greatly enhances mobility, allowing the machine to move easily through workshop aisles, quickly access elevated work platforms, narrow equipment gaps, or outdoor construction sites. It enables "mobile instant cleaning" for scenarios such as molds, large steel structures, and welding stations, significantly reducing costs associated with workpiece handling and production line downtime.

Intelligent Cleaning for Precise Process Control

Equipped with a high-definition LCD touchscreen and an intuitive graphical interface, the machine makes parameter setup straightforward. Its core scanning system supports eight programmable scanning modes (such as raster, spiral, and rectangular fill). Users can flexibly customize cleaning paths, spot overlap ratios, and energy distribution based on the geometry, material properties, and type of contaminants on the object being cleaned. The exclusive auxiliary focusing device automatically locks onto the optimal working distance during operation, fundamentally avoiding uneven cleaning or inefficiency caused by manual focusing errors. This ensures that every inch of the surface is treated evenly, consistently, and reliably.

Purely Eco-Friendly, Upholding Green Manufacturing Commitments

The cleaning process entirely eliminates the need for chemical solvents, abrasives, or other consumables. It relies solely on the interaction between high-energy laser photons and surface contaminants to achieve instantaneous vaporization or removal of stains. The operation produces no toxic emissions, no dust dispersion, and no liquid residue, fundamentally preventing secondary pollution. This not only provides operators with a safer and healthier working environment but also perfectly aligns with the stringent standards for ultra-high cleanliness and zero-pollution processes in industries such as electronics and semiconductors, aerospace, and food packaging machinery.

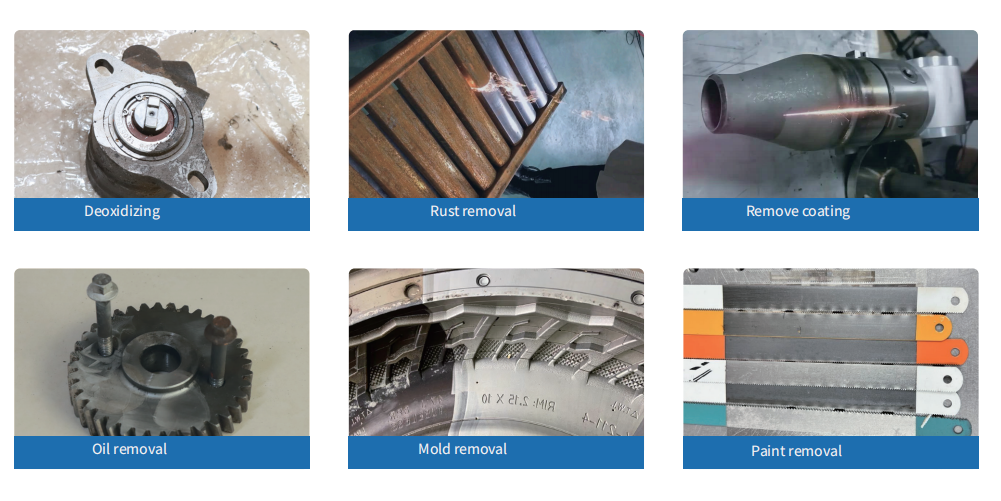

Strong Adaptability, Covering a Broad Range of Industries

Thanks to its adjustable pulse parameters (pulse width: 20–500 ns, frequency: 1–3000 Hz) and multiple focal length field lens options, the machine can intelligently tackle various cleaning challenges—from light oil stains to thick oxide layers, and from polymer coatings to metal weld slag. Its applications have successfully penetrated and served multiple key sectors of the national economy, forming a comprehensive coverage network spanning from precision manufacturing to heavy equipment, and from cultural heritage preservation to cutting-edge defense technology.

In-Depth Solutions for Typical Application Scenarios:

Intelligent Mold Maintenance and Performance Enhancement Solution

For residues such as release agents, carbon deposits, and oxides on the surfaces of injection or die-casting molds, laser cleaning enables non-contact precision removal. Without disassembling the mold, operations can be performed directly on the machine. This not only restores the mold's surface smoothness and ensures product quality but also clears fine vent holes, significantly extending mold service life, reducing maintenance downtime, and improving overall production efficiency.

Comprehensive Quality Control Solution for Welding Processes

Before welding, the laser can thoroughly remove oil stains, rust, and coatings from the area to be welded, creating optimal metal surface activity and enhancing welding strength and consistency from the source. After welding, it efficiently removes slag, spatter, and oxidation discoloration around the weld seam, resulting in a clean and aesthetically pleasing weld bead that meets high standards for appearance and non-destructive testing. This achieves a closed-loop, one-stop cleaning process for welding operations—from pre-treatment to post-finishing.

Restorative Cleaning Solution for Cultural Heritage and Building Facades

For precious cultural artifacts such as ancient stone structures, metal components, and statues, traditional cleaning methods are highly prone to causing erosion or wear. Through precise energy control, laser cleaning can gradually strip away surface contaminants, graffiti paint, or harmful salts without damaging the historical patina or original texture. This provides a revolutionary "minimally invasive" cleaning method for cultural heritage preservation.

Reliability and Safety Assurance Solution for High-End Aerospace Components

Critical components such as aircraft engine blades, turbine discs, and fuselage structures require extremely high standards for surface cleanliness and integrity. Laser cleaning can thoroughly remove oxides, thermal barrier coating residues, and various contaminants without introducing stress or altering the metal phase structure. It meets the ultra-high cleanliness standards required for component refurbishment, inspection, and pre-assembly, making it a key technological process in ensuring the safety and reliability of aircraft.

The trolley-type pulsed laser cleaning machine (air-cooled) is no longer merely a device that replaces traditional processes. It has become an important technological engine driving various industries toward more efficient, greener, and smarter production models.

Submit this form and we will contact you soon