Source:LZY Release Time:2025-12-12

In today’s pursuit of efficient and green manufacturing, traditional cleaning methods—such as sandblasting and chemical etching—increasingly reveal drawbacks like high pollution, high consumable usage, and potential damage to the substrate. Industrial cleaning is in urgent need of transformation.

As a technology that "reduces consumables, reduces damage, and reduces pollution," laser cleaning is becoming a key solution for industrial manufacturing cleaning. Let’s share some core insights to help you understand how laser cleaning can "lighten the load and enhance efficiency" for your company.

Insight 1: Reducing Consumables — Zero Chemicals, Eliminating Ongoing Costs

Traditional Pain Points:

Reliance on sand, chemical solvents, etc., leads to ongoing procurement costs and challenges with waste disposal and environmental compliance.

Our Solution:

Laser cleaning uses just one beam of light as its "tool." No chemical agents or abrasives are needed throughout the process, fundamentally eliminating consumable costs. Residue from cleaning is mainly in powder form, which can be centrally collected and recycled, creating truly green, zero-pollution manufacturing.

Our Tip: When calculating cleaning costs, include hidden expenses such as consumable procurement, waste disposal, and environmental compliance. The long-term economic and environmental advantages of laser cleaning are unmatched.

Insight 2: Reducing Damage — Precise Control, Zero Substrate Damage

Traditional Pain Points: Mechanical cleaning causes stress; chemical cleaning causes corrosion. Even minor errors can damage precision parts, leading to irreversible losses.

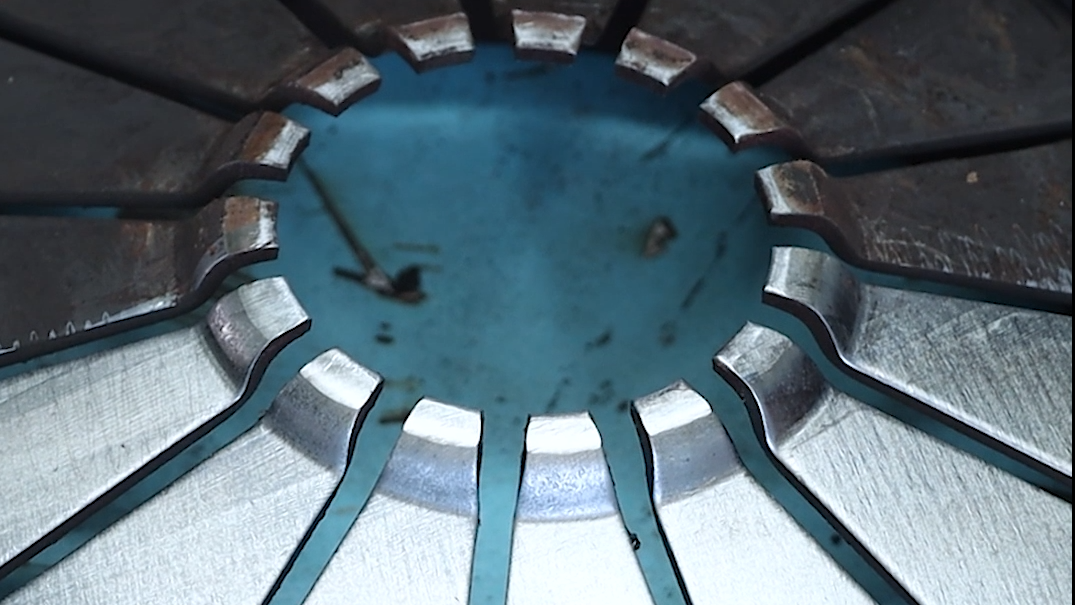

Our Solution: Laser cleaners use precise pulsed lasers. By adjusting parameters such as power and frequency, energy can be precisely controlled to ensure that only surface contaminants (rust, coatings) absorb the light, causing them to vaporize or vibrate off instantly, while the substrate remains completely unharmed.

Our Tip: For industries that cannot afford damage—such as mold repair, aerospace, and precision components—the non-destructive nature of laser cleaning is key to preserving product value. For these applications, we recommend our Cabinet Pulsed Laser Cleaning Machine.

Designed for complex, precision, and large-scale surface cleaning, this machine efficiently removes oxides, paint, oil, and other surface contaminants. Parameters are flexibly adjustable, with no thermal effect or substrate damage. It operates with high efficiency and stability, low running costs, and supports handheld or integrated automation. Suitable for hard-to-reach or high-risk areas where traditional methods fail, ensuring personnel safety.

Insight 3: Reducing Complexity — Flexible & Portable, Reaching Every Corner

Traditional Pain Points: Large equipment is immobile, making complex curves, edges, and gaps hard to clean.

Our Solution:

Pull-Rod Design: The entire unit weighs only 25kg, making it a "mobile cleaning expert" that can easily reach any job site.

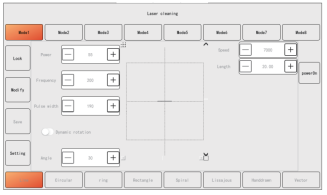

Multiple Scanning Modes: Supports 8 customizable cleaning patterns, adaptable to different shapes and materials.

Long Cable Option: The cabinet cleaner’s output cable can be customized up to 10m, greatly extending the operating range.

Our Tip: Combining the mobility of the pull-rod type with the automation interface of the cabinet type (compatible with robotic arms) covers nearly all scenarios, from on-site maintenance to smart production lines.

Insight 4: Reducing Inefficiency — Smart Operation, Mastery in Five Minutes

Traditional Pain Points: Traditional equipment is complex to operate, requires skilled workers, and involves lengthy training.

Our Solution: Simplify the process. Equipped with an intuitive LCD touch screen and a user-friendly operating system, operators can learn to use it independently after just five minutes of training. Multiple preset modes make cleaning as easy as "selecting a smartphone camera mode," greatly reducing reliance on skilled labor and improving operational efficiency.

Our Core Recommendation: How to Choose the Right Model?

Follow this simple "either-or" principle to quickly identify your ideal solution:

Choose the Pull-Rod Pulsed Laser Cleaning Machine if:

Your needs include: mobile operation, frequent site changes, cleaning small-to-medium parts, or on-site maintenance.

Typical applications: Automotive manufacturing and repair, mold cleaning, construction weld cleaning.

Choose the Cabinet Pulsed Laser Cleaning Machine if:

Your needs include: large-scale, high-intensity, automated cleaning, or extremely precision-sensitive workpieces.

Typical applications: Aerospace, rail transportation, shipbuilding, and smart production lines integrated with robotic arms.

Doing less to achieve more.

Our laser cleaning machines reduce burdens and increase efficiency and value.

We are committed to being your reliable partner in smart manufacturing. For inquiries or customized solutions, feel free to contact us anytime!

Submit this form and we will contact you soon